The Difference Between Paper, Card, and Boxboard Thickness and How to Measure It?

When working with different materials for packaging and printing, understanding the thickness of paper, card and boxboard is important. Each type of material has its unique thickness and purpose, affecting the final product’s durability and look. This guide will explain the differences and show you how to measure these materials effectively.

Table of Contents

TogglePaper Thickness

Paper thickness measures the thickness of a single sheet of paper. It is usually given in millimeters (mm) or points (pt), with one point being 0.001 inches. Paper thickness affects its feel and performance in printing and packaging.

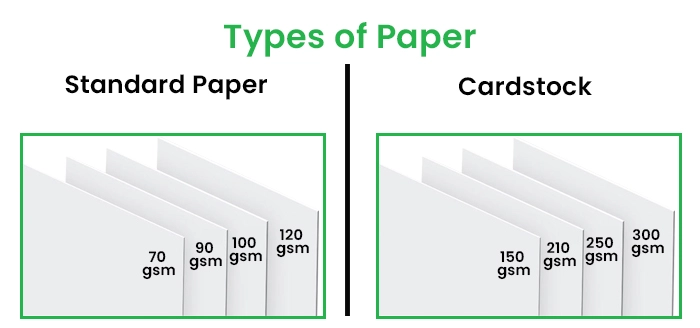

Types of Paper

- Standard Paper

Commonly used for everyday tasks like printing letters and reports. It typically ranges from 70 to 120 gsm (grams per square meter).

- Cardstock

Heavier and used for business cards and postcards, with thicknesses ranging from 150 to 300 gsm.

Applications

Paper is used in custom-printed cardboard boxes and lighter packaging materials. Its thickness affects the durability and rigidity of the final product.

Card Thickness

Card thickness refers to the thickness of a piece of card. It is thicker and more rigid than standard paper and measured in millimeters or points.

Types of Card

- Greeting Card Stock It usually ranges from 200 to 300 gsm, giving cards and invitations a substantial feel.

- Cover Stock is used for more rigid items like book covers and packaging inserts, with thicknesses ranging from 300 to 400 gsm.

Applications

The card is used in printed rigid boxes and custom printed cardboard boxes. It adds strength and durability, making it suitable for products needing a more significant packaging material.

Read Also: What is a Rigid Box?

Boxboard Thickness

Boxboard is a thick, strong paperboard used to make boxes and cartons. It is thicker than a card and has a rigid structure. Boxboard thickness is measured in millimeters and comes in various grades.

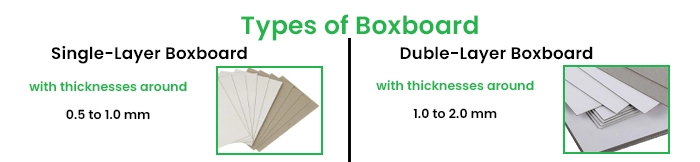

Types of Boxboard

- Single-Layer Boxboard Often used for lightweight boxes and packaging, with thicknesses around 0.5 to 1.0 mm.

- Double-Layer Boxboard Provides extra strength for more robust packaging solutions, with 1.0 to 2.0 mm thicknesses.

Applications

Boxboard is commonly used for candle boxes and custom Mylar bags. Its durability makes it ideal for protecting products during shipping and handling.

Read Also: What is the best packaging for candles?

How to Measure Thickness ?

Exact thickness measurements make sure your packaging materials meet your needs. Here’s a simple guide on measuring paper, card, and boxboard thickness:

Tools Needed

- Caliper An exact tool for accurate thickness measurement.

- Micrometer Measures minimal thicknesses.

- Ruler For rough measurements, though less accurate.

Steps to Measure Thickness

1: Preparation

- Make sure the material is flat and free from wrinkles or creases. If measuring multiple sheets, stack them evenly.

2: Measurement with a Caliper

- Open the caliper and place the material between the measuring jaws.

- Gently close the jaws until they touch the material.

- Read the measurement from the caliper’s scale.

3: Measurement with a Micrometer

- Place the material between the micrometer’s anvil and spindle.

- Turn the micrometer’s ratchet until it is tight against the material.

- Read the measurement from the micrometer’s dial.

4: Measurement with a Ruler

- Place the ruler on a flat surface.

- Meet the edge of the material with the ruler.

- Measure the thickness at several points to make sure consistency.

Why Thickness Matters?

Choosing the Right Material

Understanding the thickness helps you pick the best material for your packaging needs. For example, custom Mylar bags often need a specific thickness to make sure durability.

Impact on Durability

Thicker materials usually offer better protection. For candle boxes, a thicker boxboard keeps the product secure during shipping.

Aesthetic and Functional Quality

The material’s thickness affects not just durability but also appearance and functionality. For printed rigid boxes, the right thickness make sure a professional look and feel.

Practical Tips for Measuring and Choosing Material Thickness

Choosing the right thickness for your packaging materials is important to make sure that your products are well-protected and aesthetically look good. Here are some practical tips to help you make the best choice:

Test Samples

- Try Different Thicknesses

Always request samples of various thicknesses to test their performance with your specific packaging needs. Testing different options can help you understand which thickness offers the best balance of durability and appearance for your product.

- Evaluate Performance

Assess how each thickness holds up under typical conditions, such as during shipping, handling, or daily use. Consider factors like flexibility, rigidity, and how well the material bears stress or pressure.

- Consider Printing and Design

Test how different thicknesses interact with printing processes and design elements. Thicker materials may affect how colors appear and how easily designs can be applied.

For more insight, read Why is custom packaging important for your product?

Consult with Experts

- Seek Professional Advice

If you are unsure about the best thickness for your product, consult with packaging professionals like PackagingDot who can offer custom recommendations based on your specific needs and product requirements.

- Get Insights from Industry Experts

Professionals can provide insights on industry standards and help you understand the implications of different thicknesses on functionality, cost, and visual appeal.

Summary

Understanding the differences between paper, card, and boxboard thickness, and how to measure them accurately, is important for selecting the right packaging for your products. The right thickness keeps your products safe and enhances their appearance. This guide helps you make smart decisions to achieve the best packaging results. For expert advice and high-quality packaging solutions, contact PackagingDot today. Let us help you with the perfect thickness for your custom packaging needs.